.png)

Tomorrow's Technology Today

Optical Sensing Solutions, IoT

Indian River Inlet Bridge

.png)

About The Bridge

The Indian River Inlet Bridge (officially the Charles W. Cullen Bridge) is a cable-stayed bridge in Delaware. The bridge carries four lanes of traffic over the Indian River Inlet which connects Indian River Bay and the Atlantic Ocean. The bridge is 2,600 feet (790m) long and 107.66 feet (32.81m) wide, with a span of 950 feet (290m) and an overhead clearance of 45 feet (14m). Construction began in 2008, and the bridge was opened in January 2012.

Objective

ChM4 contracted by Cleveland Electric Labs (CEL) to bid and design the project winning this opportunity to prove in a new concept using optical sensors. ChM4 project managed, designed and provided installation of an all optical sensor system and implementing software for this revolutionary first of its kind in the United States for new construction design build project. Delaware University (UD) issued the contract for the system for long term monitoring and to evaluate the structures design with students creating thesis based on data from the SHM system developing white papers for the bridge industry. UD with funding from the FHWA, Homeland Security and Delaware DOT issued a contract to implement this state of the art SHM system. ChM4 trained UD to use optical sensors networking capabilities and a part of our installation team from day one. The optically-based structural monitoring system was embedded in the bridge concrete during construction to provide baseline information upon bridge construction and opening for later comparison during bi-annual inspections, and to continuously monitor performance over time. This system has optical strain sensors embedded in deck concrete, stay cable/deck and pylon accelerometers, tilt meters on the deck and pylon tops, expansion joint displacement sensors/pylon deck movement, and weather stations to evaluate the effects of age, and other unforeseen environmental effects. The system also incorporates an all optical security system with cameras that are tied to sensor readings, enabling remote monitoring by DelDOT personnel for structural and security purposes. The SHM system will be in use for the life of the Bridge with ChM4 continued support contracts to maintain DelDOT Servers remotely using our IntelliOptics® software monitoring package.

Review these Sites: DeLDOT, Delaware University , FaceBook and Twitter, to search for White Papers, Articles and Thesis written about this unique Optical System.

IRIB 3D model used to determine installation strategy, sensor locations and zones in IntelliOptics® monitoring software

SHMS Optical Sensors and Optical Trunk Cable Routing Map

SHM System:

Luna equipment and Sensors (2) Luna Interrogators, (2) optical multiplexer, optical sensors (68) os3600 strain sensors with onboard temperature compensation embedded in the concrete decks and pylons, (4) 0s4350 temperature absolute sensors for environmental purposes, (44) os7100 accelerometers to make up 10 Uniaxial for stay cable signature sampling and 17 Biaxial for bridge deck and pylon signatures, (9) FBG Korea tilt sensors for bridge deck and pylons, (3) CEL (Cleveland Electric Labs) optical displacement sensors to monitor expansion joint (12 inch displacement) and pylon to deck movements (24 inch displacement) and (10) experimental optical corrosion sensors. Total SHM optical sensors 218.

Analog to Fiber:(6) Rohrback corrosion sensors three depth ladder design with , (2) Young ultrasonic weather stations, one located at roadway deck level with one located at the top of pylon and (5) Bosch cameras with infrared for night vision used for security and SHM purposes.

Homeland security sensors:

ChM4 designed optical door sensors (9) for pylon hatch doors, pylon entry doors and Hub House control room door, (16) Luna os3155 strain sensors with temperature compensation mounted to (4) Pylon platforms and (1) CEL platform for entry with embedded FBG sensors to Hub House by measuring weight for alerts at these locations. The Bosch camera would train on these locations should an alarm be triggered.

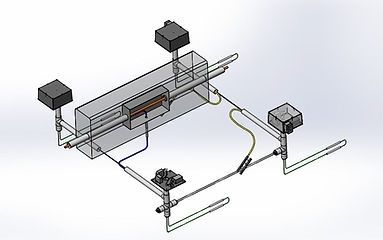

Interrogator/Multiplexer A Deck Boxes

Design shown is optical cable and strain sensors embedded in concrete to transition to master deck boxes on bridge concrete deck surfaces containing tilts and accelerometer optical sensors. This also facilitated the transition to main optical trunk line ran in pedestrian barrier conduit routed to Hub House were the optical control panel is located beneath north end of the IRIB Bridge . The drawings depict how the two optical Interrogators / multiplexers and sensors are distributed to the instruments.

Optical Transition Design to Pedestrian Barrier

Deck Box Design

The above Design is shown compressed for clarity purposes. This scheme was repeated for each section pour of the bridge deck for strain sensors embedded in concrete and both optical / analog corrosion systems embedded using the deck box transitions. The deck plates for deck boxes are wet set while the concrete is being poured in each section containing tilt sensors and accelerometers. Other deck boxes used for final optical splicing throughout the bridge length repeating this as a standard.

Stay Cable Optical Accelerometer mountings at ten locations with rotational design to angle accelerometers according to stay angle when installing and transition to Master Deck Boxes.

Cleveland Electric Labs Long FBG Pylon Displacement Sensor for deck to pylon movement monitoring.

Optical Door Sensors

Security of all pylon entrance Doors (shown above) and tops of pylon Hatch Doors (shown below) with optical FBG Door sensors designed by ChM4 mounted to door frames for unauthorized entry alerts. On all platforms entrances to pylons we mounted Luna os3155 strain sensors mounted to the underside of platform to set alarms by weight should unauthorized persons enter these locations.

Hach Door FBG Sensors

Security camera in hub house located under the north end of the IRIB bridge where optical control panel is located. The hub house has a yellow fiberglass platform at its entrance. The platform design by Cleveland Electric Labs with fiber optics embedded and can determine weights or persons at the door area for pre warning of unauthorized entry. The entry doors also has the optical FBG Door sensors designed by ChM4 mounted to door frames for detecting unauthorized entry.

TMC Command and Control Center monitoring through the TMC virtual servers and the engineering staff use a app of remote IntelliOptics® on their work stations to monitor IRIB.

Central Master Control Panel with Redundant Design Located at the IRIB Hub House at the north end of the IRIB Bridge.

SHMS Software

Security Software

IntelliOptics® structural health monitoring and security software, developed by ChM4 is a powerful, user-friendly interface that collects data from multiple sensor types and displays status information via one centralized program. We feature additional software for our Intelli-Insight® predictive analysis module for maintenance of critical structures is a new product.

|  |  |

|---|---|---|

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

ChM4 structural health monitoring installation pictures of FBG optical sensors, corrosion, weather stations, homeland security system, control panel and software turnkey project. Pictures are examples showing optical transitioning of optical cable in concrete before and after pouring at form locations.

ChM4 and CEL Project Video