.png)

Tomorrow's Technology Today

Optical Sensing Solutions, IoT

Vicksburg Mississippi River Bridge

ERDC’s Structural Health Monitoring System earns Fiatech CETI Award

About The Bridge

The Bridge opened on February 14, 1973. The Vicksburg I-20 Bridge is a cantilever bridge that crosses over the Mississippi river from Delta, Louisiana to Vicksburg, Mississippi. It is a four Lane Highway Structure 1-20 / US 80. Traffic: Vehicle 35,000/day Length: 12,974 feet (3,954 m), 7 spans, (Longest Spans ,1870 feet (265 m) Width 60 feet (18m). The customer, Concurrent Technologies Corporation, DOD, and US Army Corps of Engineers chose ChM4 Inc. as the System Integrator to design, install, and monitor the system due to the vast experience in optical sensing systems.

.Objective

There are bridges in the United States that are considered essential in case of a national emergency to supply commerce to various states. The I-20 falls in this category prompting CTC and The Corp of engineers to implement this monitoring system for this purpose and to learn the capabilities of fiber optical monitoring systems. ChM4 was awarded this turnkey project to monitor the integrity and behavior of the bridge structure, and effects due to high traffic, heavy truck loads and a fault line movement between two piers that caused damage shutting the bridge down. After repairing the bridge expansion joints was redesigned to accommodate large movements that may occur at this fault line and to monitor for any future damage caused by barge impacts or fatigue to determine the bridges life expectancy. This bridge application deployed several new features in bridge applications, including sensor activated cameras, a weather station, backup power supply, security features for hatch doors and control panel security matts, a corrosion system, accelerometers, Strain, Temperature, displacement, optical water depth pressure sensor to determine the Mississippi water level and barge impact system. The system fully integrated with IntelliOptics® monitoring software with graphical interface and sophisticated SQL for data analysis.

Model and Sensor System Map

ChM4 designed the system to have only one DAU control panel using optical sensors combining analog Cameras with a wireless mesh system making the system simple to install. We installed the shown system in 4 weeks. The SHMS was hosted on an Azure cloud website allowing access from any location with proper credentials. A simple model built used for pre-assemble of sensor system and location approvals. The model also used for the cloud SQL user interface software IntelliOptics®. After comparing optical equipment on the market Luna equipment and optical sensors was used consisting of, (1) Luna Interrogator, (1) sm041-416 optical multiplexer, (40) os3150 strain sensors, (20) 0s4350 temperature sensors, (30) os7100 accelerometers to make up 10 triaxial units, (6) FBG Korea tilt sensors, (2) FBG Korea optical pressure sensors for Mississippi River water depth, (8) CEL (Cleveland Electric Labs) 18 inch optical displacement sensors to monitor multiple expansion joints, (4) Rohrback analog RCS-36 corrosion sensors and a stand alone atmospheric corrosion rack, (6) ChM4 designed security hatch door sensors and (1) optical security matt so if intruders without authorization approach the control panel these sensors prompt email alerts to the command and control center, a separate 5 hour UPS backup, redundant communications, (1) ultrasonic weather station with no moving parts, and (3) Bosch Cameras, 2 on the Vicksburg car bridge, 1 solar powered camera on the adjacent rail bridge for viewing barge traffic and specially designed expansion joints that moved up to 18 inches due to fault line movement.

Barge Impact System

-

Barge impacts are a major concern, and their effect on the health of the bridge must be quantified. By using Luna accelerometers for pier integrity signature from steel structure and the signature of concrete piers a barge impact system was developed which serves two purposes in analyzing data.

-

On March 23, 2012, thirty barges broke lose, hitting the I-20 Bridge and adjacent rail bridge. One barge was forced dead-center on a I-20 bridge pier, then sank.

-

The system caught this event in real time and immediately alerted the local authorities, MDOT, LADOT and Corp of Engineers prior to their receiving any calls from the public upon impact.

Optical Water Level Sensor

ChM4 designed the optical pressure housing, sensor made by FBG Korea to monitor the Mississippi River water level. The housing assembly for the sensor shown below to anchor the assembly in the river base was installed by divers. This system worked in conjunction with the Barge impact system. We are the first to use this type of water level sensing in the United States that complemented the barge impact system using optical sensors.

ChM4 designed a FBG optical pressure sensor housings to monitor the Mississippi River water dept to compliment the Barge impact system,and to evaluate how piers are effected comparing water depth to optical tilts and accelerometers.

ChM4 designed a FBG optical security mat placed in front of control panel for unauthorized entry programmed into the system to alert authorities.

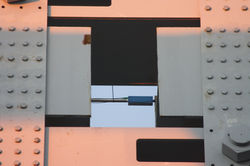

ChM4 designed the first FBG optical security switch for hatch doors. The DOD wanted to evaluate security applications using passive optics.

Hach Door Optical FBG Sensors

IntelliOptics® structural health monitoring software, developed by ChM4 is a powerful, user-friendly interface that collects data from multiple sensor types and displays status information via one centralized program. The video clip gives a 20 minute tour of the software and invite you to review its features. Also see our software section for more information and our Intelli-Insight® predictive analysis module for maintenance of critical structures.

|  |  |

|---|---|---|

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|

ChM4 structural health monitoring installation of FBG optical sensors, corrosion, smart camera system, barge impact system, water depth, control panels and software turnkey project.

© 2007 by Success Consulting